Source: GAO

WASHINGTON: The F-35 program has faced enormous challenges over the years, but the biggest today is particularly intractable: The program simply can’t keep the flow of parts moving around the world in the numbers and places necessary.

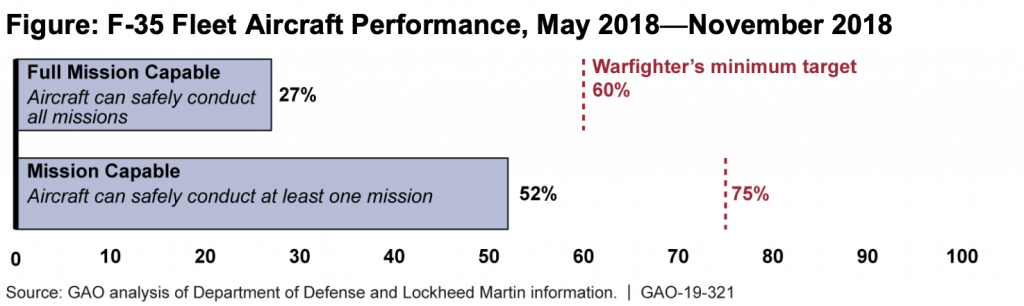

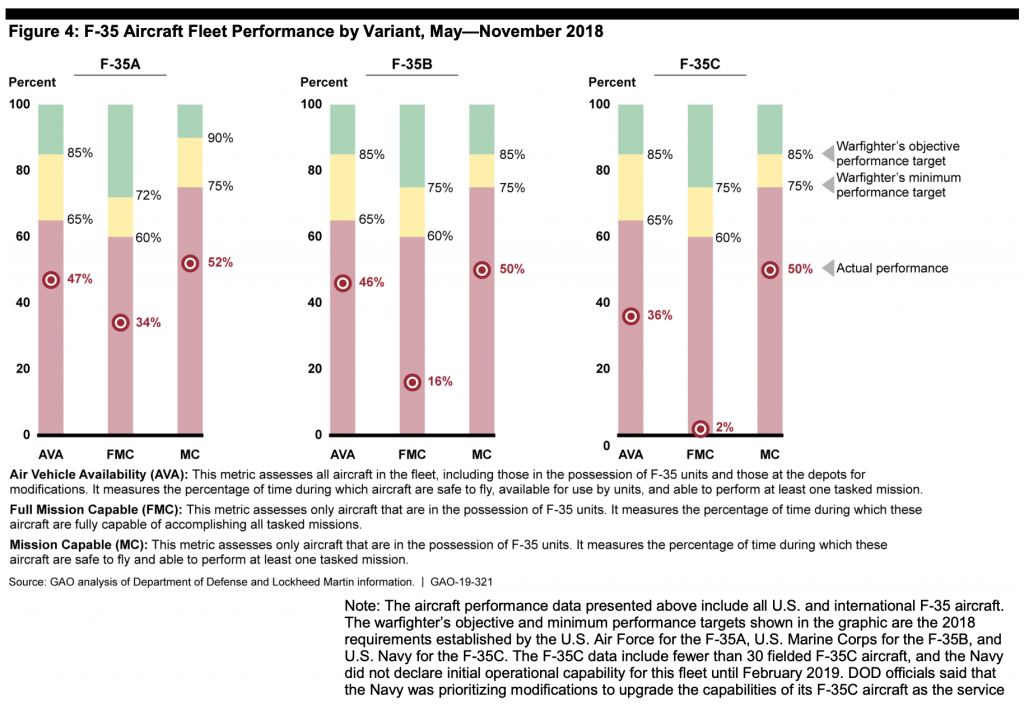

How bad is it? “F-35 aircraft performance is falling short of warfighter requirements—that is, aircraft cannot perform as many missions or fly as often as required. This lower-than-desired aircraft performance is due largely to F-35 spare parts shortages and difficulty in managing and moving parts around the world,” the Government Accountability Office said in a compelling report today. “F-35 aircraft were unable to fly nearly 30 percent of the May-November 2018 time period due to spare parts shortages. Also, the Department of Defense (DOD) had a repair backlog of about 4,300 F-35 parts.”

Former Defense Secretary Jim Mattis established a goal of 80 percent readiness for all US tactical aircraft. Lockheed Martin has pledged to meet that goal and is pouring $180 million of its own money into the computerized system known as ALIS — meant to make to F-35 planning and parts management more efficient but actually an albatross for maintainers and aircrews — to bring things back on track.

Lockheed issued this statement on April 19, saying that the plane’s “reliability and readiness continues to improve and newer production aircraft are averaging greater than 60 percent mission capable rates with some operational squadrons consistently near 70 percent. Additionally, Lockheed Martin has reduced its portion of operating costs per aircraft by 15 percent since 2015. The F-35 enterprise’s goal is to deliver 80 percent mission capable rates in the near term, and achieve a $25,000 Cost per Flight Hour (CPFH) by 2025, which is comparable to the cost to sustain legacy aircraft, while providing a generational leap in capability.”

Source: GAO

Meanwhile, the Joint Strike Fighter program has built a system to supply the US and allies with parts, but it just doesn’t the job well enough, the GAO found. “DoD purchases certain sets of F-35 parts years ahead of time to support aircraft on deployments, including on ships. But the parts do not fully match the military services’ needs because F-35 aircraft have been modified over time. For example, 44 percent of purchased parts were incompatible with aircraft the Marine Corps took on a recent deployment.” (Emphasis ours).

And things may not get much better for a while: “Without a detailed plan for the network, DOD may not be ready to support an expanding fleet.”

Two F-35C fighters during pre-initial Operational Testing and Evaluation at Eielson Air Force Base, Alaska.

The heart of the problem lies, as might be expected, at the depots where the majority of significant repairs are made, GAO says. “This backlog of parts awaiting repair is largely attributable to delays in the establishment of part repair capabilities at the military depots.” That isn’t likely to be fixed until 2024. Yes, 2024.

The system for moving parts around the world is impressively complex. As often happens with highly complex logistics system, it doesn’t always work well.

“For its supply chain construct to work as intended, F-35 parts must be able to move freely and efficiently among U.S. and international program participants, suppliers, and repair facilities, regardless of the country or company of origin. The program has projected that F-35 parts could potentially be moved on 132 different paths between participating countries (for example, Italy to United Kingdom, Italy to Norway) and 2,162 paths between F-35 sites (for example, a warehouse in the Netherlands to a base in Norway),” GAO found. That’s many, many points of possible failure or delay.

The GAO makes seven recommendations to improve parts management. The Pentagon agreed with all of them. OK. Let’s see how long it takes to hit that 80 percent readiness level.

Navy jet trainer fleet operations remain paused after engine mishap

One week after the incident, a Navy spokesperson says the service is continuing to assess the fleet’s ability to safely resume flight.