Oshkosh’s OMFV proposal is based on the Hanwha “Redback” Infantry Fighting Vehicle, shown here, which in turn derives from the South Korean army’s K21. (Hanwha photo)

WASHINGTON — In a vital vote of confidence for a once-troubled and still controversial program, all five industry teams competing to design the Army’s future troop carrier have submitted bids for the next phase, Breaking Defense has confirmed.

Now comes the hard part: turning digital designs into working vehicles. By mid-2023, the service plans to pick three teams to move on to building prototypes of a high-tech Optionally Manned Fighting Vehicle (OMFV) to replace the Reagan-era M2 Bradley. Bids were due on Tuesday.

“We’ve gotten the easy things out of the way,” one Army official told Breaking Defense, speaking candidly on condition of anonymity.

Five teams — led respectively by American Rheinmetall, BAE Systems, General Dynamics, Oshkosh and upstart Point Blank Enterprises — received contracts last year to develop initial digital designs for OMFV. Some have decades of experience making US Army vehicles, others are throwing their hats in the ring for the first time, but all have already gone through three rounds of intense feedback from the Army and revisions to their designs, increasingly converging on similar physical designs:

- a tracked vehicle (rather than wheeled) with hybrid-electric drive, which both reduces demand on fuel supplies and allows stealthier “silent watch” and “silent maneuver” modes;

- an unmanned turret boasting a 50 mm autocannon (or a 30 mm with option to upgrade), keeping the entire crew in the less exposed and heavily armored hull;

- a two-person crew — down from the Bradley’s three — assisted by extensive automation, plus passenger space for six infantry soldiers.

That’s up from the four or five fully equipped foot troops that can ride in Bradley, but down from the full squad of nine the Army hoped for with the earlier attempted programs. While painful, this reduction in crew size and passenger capacity is critical to keeping down the overall weight and volume of the vehicle, making it easier to fuel, maintain, and transport.

Because of the iterative process, the official expected that “these designs are going to be very similar on things the layman would consider, [such as] size, weight, crew, weapons. [Instead,] the differential will be along the lines of artificial intelligence, predictive maintenance.”

That the Army can afford to focus on such stretch goals shows how far the OMFV program has come since 2019, when its very survival was in doubt. But the Army’s long history of failed procurements still leaves ample reason for uncertainty. And with the driving threat for armored vehicle combat, the Russian military, disintegrating in Ukraine, the US Army has yet to make a clear case for OMFV’s relevance to a Pacific war with China.

M2 Bradley evolution (DoD photo)

But the M2 Bradley is arguably long overdue for replacement, with decades of upgrades having maxed out its electrical system and weight capacity. In fact, the mid-weight OMFV is the Army’s third attempt to replace the Bradley, which first entered service in 1981 and can sits at 25 to 35 tons depending on variant. The under-armored Future Combat System (26 tons) was cancelled 2009 after the Army spend roughly $20 billion , and the overheavy Ground Combat Vehicle (60-plus tons) was cancelled in 2014 before prototypes were even built.

RELATED: Lighter, hybrid, & highly automated: The Army’s next-gen armor

In 2019, the Army decided it needed a Bradley replacement to enter service by 2026 and the only way to meet that tight schedule was to have companies deliver full-up working prototypes — at their own expense — by Oct. 1. Only one company, General Dynamics, even tried to meet that deadline, and it was effectively disqualified for failing to meet requirements — requirements that the Army itself soon realized they were unrealistic. There was no way to carry armor thick enough to meet all likely threats and transport a full squad of nine infantry and be light enough to fit two vehicles on a C-17 air transport.

So, in a rare public reversal, the Army admitted its mistake and rebooted the program with a longer timeline, less rigid requirements and more funding for industry. In the new, multi-phase approach, the service would pay companies to develop designs before requiring them to commit to building prototypes.

RELATED: Two Men & A Bot: Can AI Help Command A Tank?

So, now, with all these commonalities, what distinguishes the different entrants? That’s hard to tell, entirely by design, because the Army and the competitors are keeping details close. But there are still clearly different approaches among the five teams.

Hanwha Redback and Reinmetall Lynx (Sgt. Jake Sims for Australian Defense Ministry)

Five Teams, Two Strategies

The five teams competing for OMFV divide, roughly, into outspoken outsiders and tight-lipped insiders.

Two companies with no track record of building heavy armored vehicles for the US Army are offering variants of existing foreign designs, and both spoke in detail for this story:

- American Rheinmetall, a subsidiary of the famous German armsmaker, is offering a version of the Lynx, already on order by Hungary. It’s partnered with Raytheon, Textron, and other US firms.

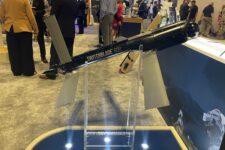

- Oshkosh, celebrated for rugged civilian and military trucks like the JLTV, has teamed with Korean conglomerate Hanwha to offer a version of the Korea Army’s K21.

A Hanwha K21 variant, the AS21 Redback, is competing with a variant of the Rheinmetall Lynx for a big Australian contract.

RELATED: Aussie Infantry Fighting Vehicle, Army’s biggest-ever contract, faces government delays

Two other teams are led by the US-based companies that, between them, have produced every US Army armored vehicle since the 1980s:

- General Dynamics makes the iconic M1 Abrams heavy tank, the MPF light tank and the wheeled Stryker.

- BAE Systems makes the M109 mobile howitzer, the M2 Bradley and its updated but downgunned support variant, the AMPV.

Both companies are drawing on their extensive experience but building all-new designs, and both limited themselves to brief, bland statements. They haven’t even released concept art of their offerings.

Then there’s the outsiders’ outsider: relatively tiny Point Blank Enterprises of Florida, best known for making body armor, which has branched out into helicopter armor and some highly sensitive surveillance vehicle programs. Point Blank has posted sleek CGI video of its OMFV concept, for which it’s partnered with several well-respected small and midsized firms. The company provided some additional information in an interview.

OMFV proposal from Point Blank Enterprises (PBE graphic)

So there clearly is a culture gap, with the competitors that are outsiders to the US armored vehicle market making a much bigger public play than the insiders with long connections to the Army’s armored corps. That said, don’t draw excessively sweeping conclusions from how much companies are willing to talk to the press. The Rheinmetall and Hanwha vehicles are already on the market, so people know a lot about Lynx and Redback already; if those teams had all-new, as-yet unseen designs like GDLS and BAE, they might be just as guarded.

“We have an all-new, purpose-built vehicle based on the Army requirements,” a BAE spokesperson said. “No vehicle available in any fleet today meets those requirements.” BAE deferred all further inquiries to press briefing set for sometime later this month.

While Rheinmetall and Oshkosh are both offering variants of existing designs, in their conversations with Breaking Defense, both companies emphasized how much they’ve changed in response to feedback from the US Army. Both Lynx and Redback have slimmed down and lost weight to meet the US requirement. Both have reduced crew from three to two and passengers from eight or nine to six. Both have moved from manned turrets to unmanned and from diesel powerplants to hybrid.

“The Australia program, it’s a much larger, much different vehicle, different number of dismounts, different capability,” said Pat Williams, Oshkosh vice president & general manger. of Army & Marine Corps programs. “The United States Army wants a much smaller, much lighter, still heavily protected vehicle with enhanced lethality and optics.”

The Army’s desires have evolved, not just industry’s designs. “The Army realized that, based on their [original] requirements, they were getting a very large vehicle,” said Michael Milner, American Rheinmetall’s director of business development & strategy. “So they went back in, they tweaked some requirements here and there, which allowed us to reduce the size of the vehicle.”

The Army has made tough trade-offs. In particular, a smaller crew gets overwhelmed more easily, with potentially fatal consequences in combat. As early as World War II, German panzers with three-man turrets – commander, gunner, and loader – consistently outfought Soviet T-34s with better guns and armor but only two men in the turret, which forced the commander to double up as the gunner, let alone French tanks with just one. With OMFV, the Army is betting heavily on automation to help maneuver the vehicle and even identify threats, although the computer won’t open fire without human authorization. For at least some missions, the Optionally Manned Fighting Vehicle could operate entirely by remote control — hence “optionally manned.”

“That’s probably one of the most challenging aspects of this program, how do I take a three-soldier crew and break that down into a two-soldier crew?” Milner said. “What can be fully automated? …What are those things that, because of current policies, you can’t fully automate, [e.g.] you have to have a soldier in the loop when you actually press the fire button? … And there some things we can’t automate at all because we’re just not there yet.”

Self-driving tanks, for instance, are proving even harder than self-driving cars. “We’re able to provide a lot of automation features and hooks for when technology’s available,” Milner said, “ [but] it’s still very difficult to drive off road autonomously.”

The new tech demands have fostered new tech partnerships. Rheinmetall has allied with defense behemoth Raytheon to launch mini-drones from Lynx and with upstart Anduril to develop autonomy software. Meanwhile, Oshkosh has brought aboard Pratt & Miller and Qinetiq, two robotics companies that together won an Army competition for an experimental unmanned scout, the Robotic Combat Vehicle (RCV) – Light.

Rheinmetall Lynx OMFV design in formation (Rheinmetall artwork)

Another critical but abstruse aspect of OMFV’s electronics is modularity: Every piece of software and hardware, from every vendor, must be compliant with an evolving Army standard known as GCIA. (That’s a mercifully short nested acronym for GCS (Ground Combat Systems) Common Infrastructure Architecture).

All the competitors have collaborated with the Army on defining the GCIA standards, Oshkosh’s Williams said, and compliance is a major criterion in the competition. “There are technical requirements for the capability and performance of the vehicle, but there’s also a significant evaluation on your ability to conduct digital engineering and compliance with the GCIA,” he said. “You’re evaluated on your ability to operate within that standard.”

“Getting that [standard] defined was really, really hard,” the Army official said — but it’s critical. The goal is to make future upgrades plug-and-play, without extensive bespoke integration traditionally required for each new feature. This way the Army can easily and affordably keep the vehicle cutting-edge throughout its decades of projected service.

In other words, what OMFV has the potential to grow into is at least as important to the Army as what it can do today.

HASC adds Virginia-class sub, cuts F-35s in $849.8 billion draft defense policy bill

The bill sticks to budget caps laid out by the Fiscal Responsibility Act.