The active duty 388th and Reserve 419th Fighter Wings conducted an F-35 Lightning II Combat Power Exercise at Hill Air Force Base, Utah, Jan. 6, 2020. The exercise demonstrated the ability to employ a large force of F-35As, testing readiness in the areas of personnel accountability, aircraft generation, ground operations, flight operations and combat capability against air and ground targets. U.S. Air Force photo by R. Nial Bradshaw

A suite of software and hardware upgrades for the F-35 Lightning II fighter – known as Block 4 – has been in the works for years, with plans to bring everything from new weapons, electronic warfare software updates, and cockpit improvements to the jet in order to counter threats from near-peer competitors like China and Russia. However, propulsion – a foundational building block of many air vehicle capabilities – has been notably absent from modernization plans until only recently.

There is now widespread acknowledgment that propulsion modernization commensurate with air-vehicle growth is necessary to fully realize Block 4 capabilities and to avoid a hefty sustainment bill for operating the current F135 engine beyond its specification, according to its manufacturer, Pratt & Whitney.

Exactly how that engine modernization will be executed – there has yet to be a defined requirement or funding – will have far-reaching implications for the F-35 program of record, taxpayers, and US’ relationships with key allies around the world. And, given the challenging fiscal environment, the decisions ahead will also play a role in determining how and when the services can afford to modernize other programs that are critical to national security.

When it comes to the path forward for F-35 propulsion modernization, Pratt & Whitney says it’s about offering the most cost-effective solution that can meet all warfighter requirements. Pratt & Whitney’s extensive 5th generation experience underwrites the company’s ability to provide a full range of modernization options for the F-35 enterprise – from enhancing the existing F135 engine to an adaptive cycle engine known as XA101 – to meet any future requirements.

Though Pratt & Whitney has multiple options available to enable tomorrow’s combat air team, it firmly believes an enhancement to the existing engine – known as the Enhanced Engine Package (EEP) – checks all of the boxes. A modernized F135 engine will meet the timeline and necessary requirements to support Block 4 aircraft without disrupting the program of record or driving increased cost and risk.

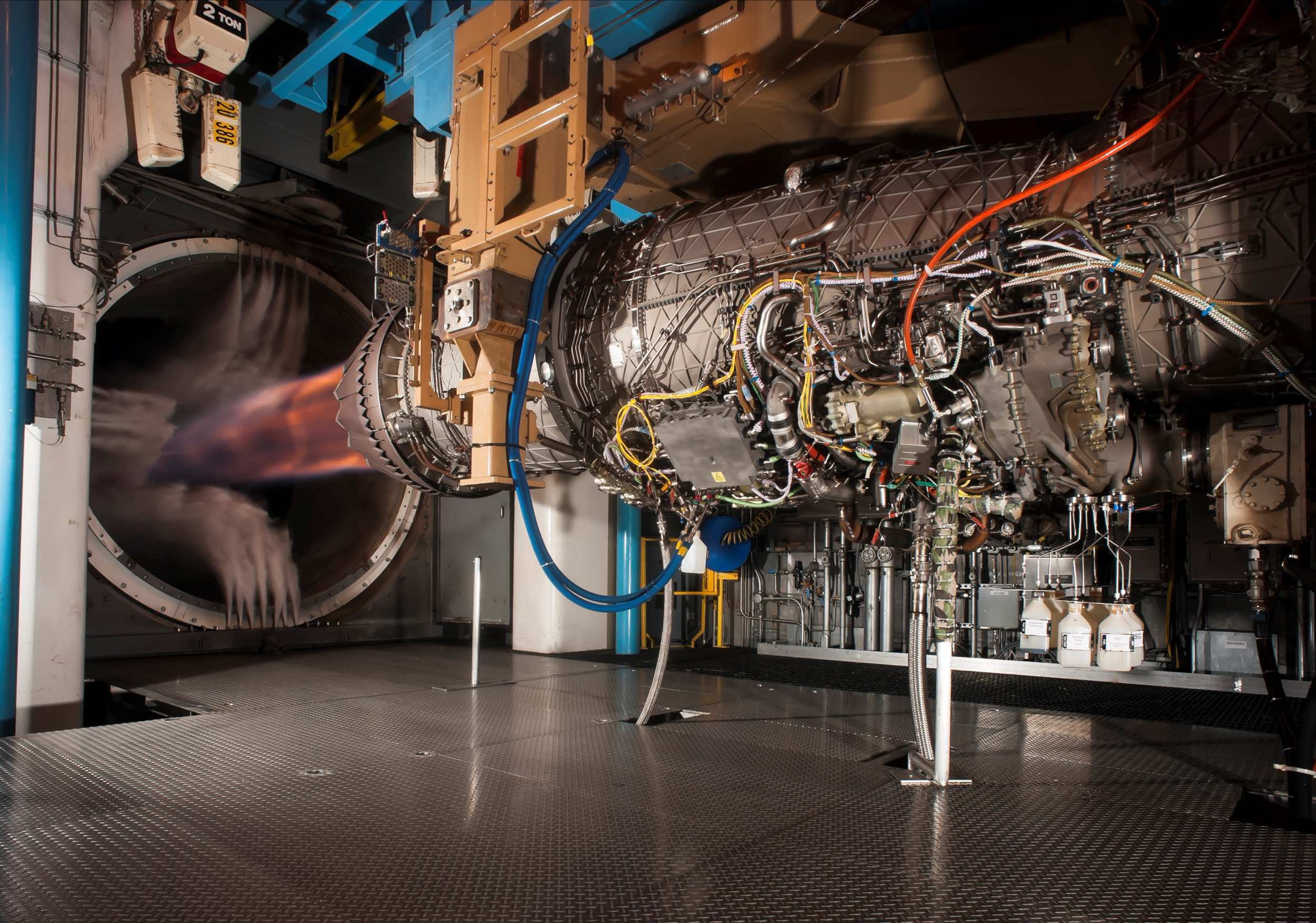

A modernized F135 engine will meet the timeline and necessary requirements to support Block 4 aircraft without disrupting the program of record or driving increased cost and risk. Photo courtesy of Pratt & Whitney photo.

Cost Effective

As the most expensive acquisition program in Department of Defense history, cost has always been the existential threat to the F-35. So when it comes to modernization, cost-effective capability growth is key. That’s why maintaining variant commonality, which has long been a foundational element of the program’s design to drive economies of scale and reduce cost, is paramount, according to Pratt & Whitney. EEP is the only variant-common modernization solution available, which reaps massive benefits in terms of cost savings.

For example, EEP leverages the existing production and sustainment infrastructure, eliminating the need to standup a duplicative and expensive sustainment network and logistics stream that would be required with a new engine. In fact, keeping the existing sustainment network as-is maintains the current cost share ratios with the services and partners – maximizing affordability for all. For one member of the enterprise to go it alone with a new engine would translate to increased sustainment costs for everyone else. It would also risk alienating key U.S. allies who have invested considerable resources into a joint program that would suddenly cost more than they’ve budgeted for.

Additionally, EEP is production-cost neutral, retaining the sizable affordability investments that have been made to date. That’s right, a modernized F135 engine off the assembly line would cost the same as the current configuration. A new engine would have to march up a steep learning curve that takes time and investment.

All told, EEP saves the taxpayer approximately $40 billion in lifecycle costs over the life of the program, making it the most cost-effective modernization available for the F-35 enterprise. Those are substantial savings that can be put to use for other modernization priorities across the Department of Defense.

Low Risk

Given that the F-35 is a single-engine fighter aircraft, low technical risk is a must for pilot safety. Based on operational experience, today’s F135 is the safest fighter engine ever produced, having demonstrated a 300-percent reduction in engine related “Class A” mishaps over previous-generation fighter engines, enabled by its advanced damage-tolerant design and fully integrated, prognostic health monitoring. That means pilots can complete their mission and return home safely, without worrying about the engine.

As a derivative design, EEP builds upon the same proven architecture that has more than one million flight hours between the F135 and the F119, which powers the F-22 Raptor. It’s a combat-tested architecture that pilots continue to trust with their lives. Weight neutral and requiring minimal airframe-integration testing, EEP was designed from the onset to be integrated into production and/or retrofit during engine overhaul – enabling the accelerated fielding of fully supported Block 4 capabilities in the capacity needed by the warfighter.

Derivative designs have been the historical norm for fighter aircraft for decades in order to minimize technical risk for the program and pilots. Examples of derivative solutions include the engines on platforms such as the F-16 Fighting Falcon, AV-8B Harrier, and F/A-18 Super Hornet. A new engine for the F-35 would mean inserting a brand new, operationally untested centerline design into a single engine jet, which has never been done in the history of the Department of Defense.

An improved F135 engine off the assembly line would cost the same as the current configuration. Photo courtesy of Pratt & Whitney.

Capable

While the F135 meets original specifications, planned air-vehicle growth associated with Block 4 will exceed the current F135’s power and thermal management (PTMS) limitations by the end of the decade. Fortunately, the F135 has ample design margin for agile and affordable enhancements.

Pratt & Whitney’s EEP offering leverages the Department of Defense’s investment in adaptive technology to deliver the required capability growth – all within the confines of the existing program construct. This means EEP incorporates the latest in propulsion technology – including advanced aerodynamics and durability component technologies – to meet or exceed the necessary requirements for Block 4, while retaining variant commonality to maximize affordability. Performance improvements include greater than 10 percent more range and thrust, greater than 50 percent more thermal management capacity as well as a 5 percent gain in powered lift for the F-35B Short Take-Off and Vertical Landing variant.

In sum, EEP can deliver the capability growth needed out of the existing engine to support Block 4 with margin – for all variants – at substantially less cost and risk than a new engine. That is a win-win for the warfighter and taxpayer.

The Takeaway

Propulsion modernization is critical to ensuring the F-35 retains its position as the cornerstone of tactical air fleets for operators around the globe, but it must be enabled by a defined requirement and funding. To date, there is not yet a defined requirement or dedicated funding for propulsion growth, which must change soon to support the modernization schedule for Block 4. However, progress has been made in recent months as there is now widespread acknowledgement that propulsion growth is needed – an important first step.

As the F-35 enterprise considers its path forward, Pratt & Whitney stands ready to support with a full range of modernization options that can meet any requirement. With the warfighter and taxpayer in mind, Pratt & Whitney believes that EEP offers the most cost effective, lowest risk growth path for F-35 propulsion modernization.