The Challenge

On today’s modern battlefield, threats to ground vehicles are continually evolving, making protection upgrades a vital necessity in order to survive, fight and win. Militaries are constantly challenged to keep pace with these ever-changing threats, but more armor and additional defensive systems can add significant weight and integration burdens while also reducing platform mobility. Taking a holistic approach to the integration of new systems has become critically important as a more efficient and effective means of increasing crew survivability.

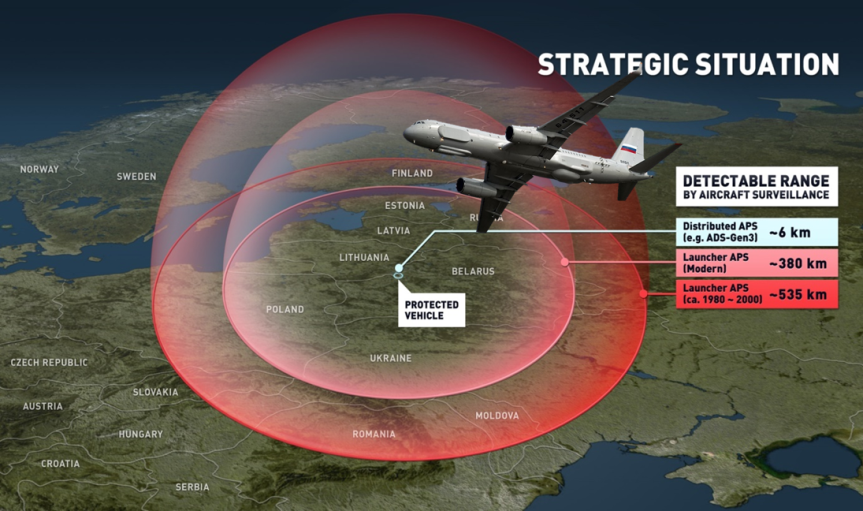

Active Protection Systems (APS) have become one of the most sought after technologies to address modern survivability challenges. But integration and fielding of “launcher style” hardkill APS on legacy fleets has been mostly limited to main battle tanks, and only after significant modification to the platforms in order to accommodate substantial APS weight and power requirements. In addition, most fielded APS systems have dramatically increased combat vehicles’ electronic signatures when in operation, making detection and targeting by adversaries much easier on battlefields where electronic sensing and warfare capabilities are ever more prominent putting the vehicle and its crew at greater risk of attack, a contradictory outcome for a technology meant to improve survivability.

The Solution – StrikeShield APS

An Impressive Heritage Leads to a New Hybrid Design Breakthrough: Rheinmetall Protection Systems began investing in the development of APS technology over 15 years ago. After more than 900 live fire tests and integration on multiple different ground vehicles, the third generation of the “Active Defense System” progressed into what is now StrikeShield: a hybrid APS solution that smartly and sleekly combines active and passive protection in a modular design that can be adapted to most platforms to combat continually evolving threats. This hybrid approach leverages Rheinmetall Protection Systems’ substantial expertise in both APS and vehicle armor to produce a combined system that achieves optimal performance while minimizing system weight and power consumption.

Unlike older launcher style Active Protection Systems, StrikeShield’s hybrid design is comprised of armored modules that house the system’s radar, electro-optical sensor, cabling and countermeasures. These modules are mounted at multiple locations around the host platform to ensure the coverage and redundancy necessary to effectively defeat multiple and simultaneous attacks. The protection of the armor increases the survivability of not just the vehicle but also the StrikeShield components themselves.

More importantly, the hybrid design greatly reduces the risk of residual damage after an incoming threat has been intercepted by the system. This is a key differentiator and a critically important advantage, particularly for less heavily armored vehicles.

StrikeShield’s design also enables it to defeat enemy fire even when it comes from distances as close as 10 meters, as might occur when operating in a dense urban environment, a capability that launcher style APS cannot replicate.

Finally Solving the Stryker APS Conundrum: Although the Stryker Infantry Carrier Vehicle (ICV) is a key component of the Army’s ground combat vehicle fleet and vital to infantry maneuver, the Army has yet to field an Active Protection System on this platform. The only combat maneuver brigade permanently assigned in Europe is, in fact, a Stryker brigade. StrikeShield would enable a game changing improvement in Stryker survivability due to the system’s hybrid design which combines APS and upgraded armor in a modular solution for enhanced protection against RPG’s, ATGM’s and other anti-armor threats, delivering both the ability to disrupt incoming munitions as well as the enhanced passive armor needed to enable the Stryker to survive remnant projectile materials that reach its surfaces. As the Army invests substantial resources into upgrades like the 30mm unmanned turret and the double-V hull in order to make the Stryker more lethal and capable, fielding an APS solution that will significantly increase Stryker survivability is now more critically important than ever.

Smaller Electronic Signature and Near Field Intercept of Threats are Key to Ensuring a Survivability Technology Doesn’t Inadvertently Make a Platform Less Survivable: StrikeShield’s distributed architecture and extremely fast processing speeds enable the very precise intercept of incoming threats at a point near the platform. This helps to mitigate the effects of the blast and minimizes the risk of collateral damage to dismounts or nearby civilians because the remnants of the defeated projectile have a smaller area to disperse across.

Equally importantly, StrikeShield’s ability to detect, track and intercept incoming threats so quickly results in sensors that only need to survey about 35 meters from the host vehicle. To achieve this, the system uses low-powered radar with a very small electronic signature that is exceptionally difficult for adversaries to detect. This is in stark contrast to high-powered radars used in launcher style systems that sense out to far distances but give off large electronic signatures an enemy can detect and use to target the vehicle from afar.

Vulnerabilities from the electronic signature of formations that have fielded APS were highlighted by U.S. Army opposition forces (OPFOR) at the National Training Center in Fort Irwin, California, where they found they could identify formations by their electronic warfare footprint and defeat them with stand-off capabilities, like artillery, long before the systems could even enter a force-on-force fight.

Photo credit U.S. Army. “This Is What Ground Forces Look Like To an Electronic Warfare System and Why It’s A Big Deal”. The Drive, by Joseph Trevithick, 20 May 2020

Ready for the Next Challenges in APS Growth – Kinetic Energy Penetrator Defeat: StrikeShield’s unique speed and short reaction time also mean it has increased potential to achieve the defeat of much faster kinetic energy (KE) threats such as long rod penetrators in tank munitions, a feat highly desired in APS but not yet fully achieved by any fielded system. In recent testing, Rheinmetall has successfully demonstrated concepts to achieve KE defeat with the StrikeShield system and is working to further develop this exciting next-generation capability.

Ready Now

In May 2021, Rheinmetall announced that it will equip 209 Infantry Fighting Vehicles ordered by the Hungarian Army with the innovative technology found in StrikeShield APS. The maturity and adaptability that StrikeShield offers is an important capability for both legacy fleets and future vehicle programs. The system provides unique advantages as either a subsystem in a modular vehicle protection suite or as a standalone hardkill APS solution.

In full perspective, StrikeShield is poised to provide critical KE defeat capabilities that are highly desirable for the tank forces of today and tomorrow; to enable game changing survivability improvements for next generation infantry fighting vehicles emerging around the globe; and to solve the enduring challenges of protecting more lightly armored wheeled combat platforms like the Stryker ICV – and, in each case, doing so without exacerbating the weight, power and electronic signature challenges experienced with many other systems.

StrikeShield is offered in the US by Rheinmetall and its partner Unified Business Technologies, Inc. (UBT) headquartered in Troy, MI.

For more information on StrikeShield APS contact: Roy McCallum, Vice President of Sales – North America, roy.mccallum@americanrheinmetall.com