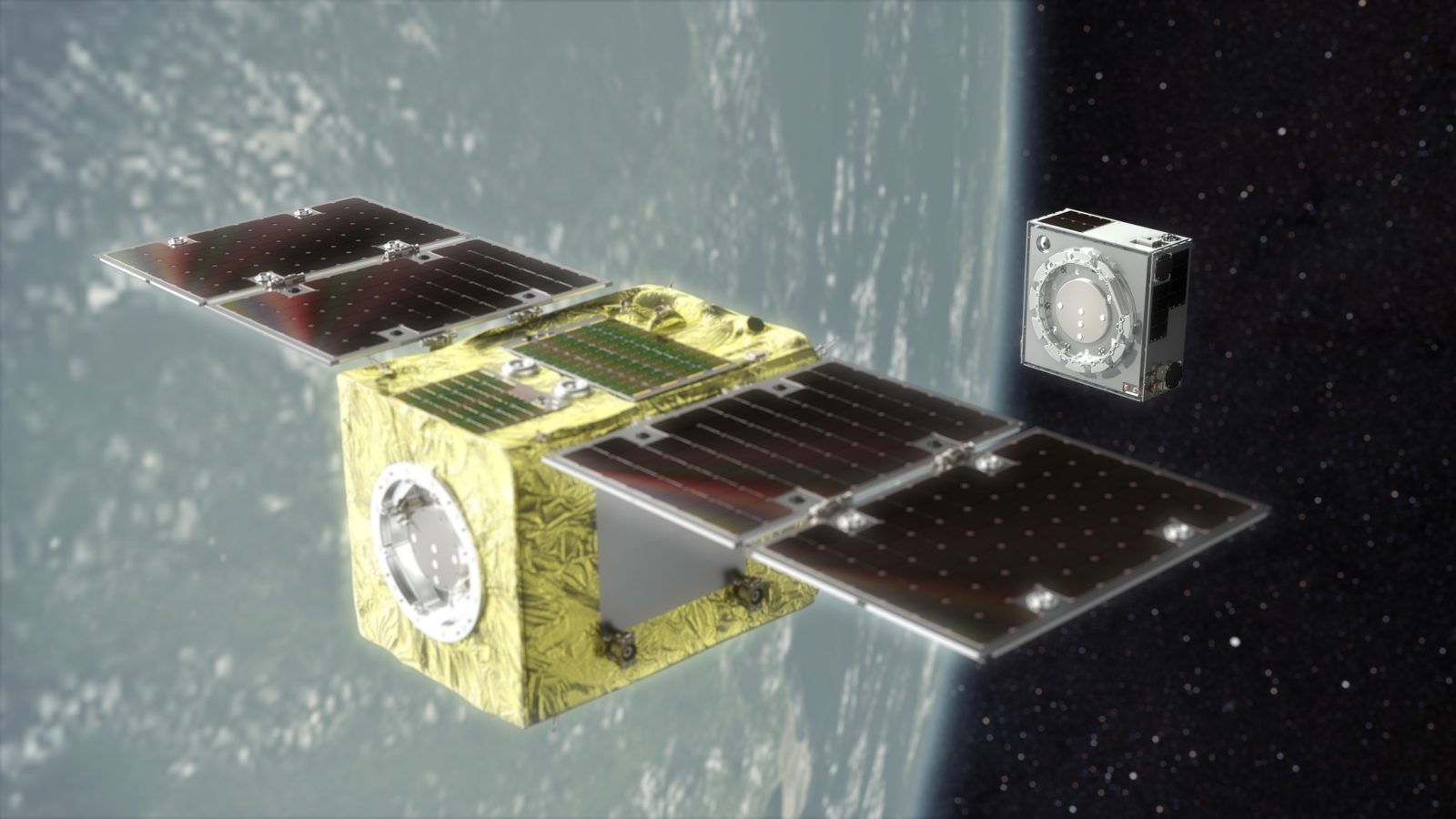

Astroscale’s End-of-Life Services by Astroscale-demonstration (ELSA-d) spacecraft. (Astroscale)

WASHINGTON — In recent months the Air Force Research Laboratory has been expanding its collaboration with commercial industry on technologies to inspect, repair and refuel satellites on orbit — not to extend the lives of just any satellites, but especially those responsible for keeping an eye on adversary spacecraft and potentially dangerous space junk.

AFRL’s Tristan Griffith directly linked “rendezvous, proximity operations and docking,” or RPOD, to future space situational awareness (SSA), saying that it was a “critical” component.

“RPOD maneuvers are absolutely relevant to SSA. In order to retain effective SSA, AFRL must continue developing RPOD technologies for orbital sustainment. Inspection, troubleshooting, and maintenance are all components of RPOD maneuvers relevant to SSA,” he told Breaking Defense in December.

Griffith is responsible for managing AFRL’s latest Cooperative Research and Development Agreement (CRADA), signed with the US arm of Japanese firm Astroscale in November, to explore the potential for commercial capabilities to help AFRL get RPOD technologies into the hands of Space Force Guardians.

“There are a number of CRADAs at AFRL supporting rendezvous and proximity operations and especially docking technologies,” Griffith noted, pointing for example to an 2021 agreement with Orbit Fab to explore on-orbit refueling operations.

The collaboration with Astroscale also “advances several of the strategic goals set forth in the National ISAM Strategy,” according to AFRL’s CRADA manager Jason Guarnieri.

While the details have yet to be nailed down, Astroscale US President Ron Lopez told Breaking Defense that the no-cost cooperative agreement will focus on ground testing of the company’s hardware and software at Kirtland AFB in New Mexico.

“Generally speaking, what we plan to get out of it is the use of some of the fantastic facilities that exist down there at Kirtland to do some testing and de-risking and maturing of technology that we wouldn’t be otherwise able to do, at least not [in a way that is] economically feasible,” he said. “And I hope that what AFRL gets out of it is a better understanding of some of the cutting edge technology that Astroscale is developing — some of the core technologies, the algorithms, the know-how, how we integrate sensors into our solution — that are really going to underpin the ability to do RPOD safely.”

Demonstrating that such close-in maneuvers and spacecraft docking can be done safely, Lopez added, “will enable on-orbit servicing, which in turn, … is what is going to underpin the growth of that trillion dollar economy that everybody talks about, but also underpins that in-space logistics chain talked about in the USAF 2030 Science and Technology Strategy. Space is the only domain of military operations that does not have a logistics tail, and that’s changing now.”

According to a paper [PDF] by the American Institute of Aeronautics and Astronautics, “Space logistics is the science of planning and carrying out the movement of humans and materiel to, from and within space combined with the ability to maintain human and robotics operations within space.”

Griffith explained that space logistics “is especially concerned with support for military equipment and personnel through the entire space domain.”

Further, he added, “Industry has already demonstrated the utility of reusable spacecraft, which is utility AFRL recognizes. A number of academic researchers and startups are proposing on-orbit additive manufacturing. An example mission might encompass hardware and software upgrades to an asset, or the replenishment of consumables on another.”

Space Force EW unit working to integrate new weapon systems, intel personnel

The Space Force’s Delta 3 is responsible for organizing, training and equipping Guardians for electronic warfare missions involving satellite communications, as well as sustaining related offensive and defensive EW systems.