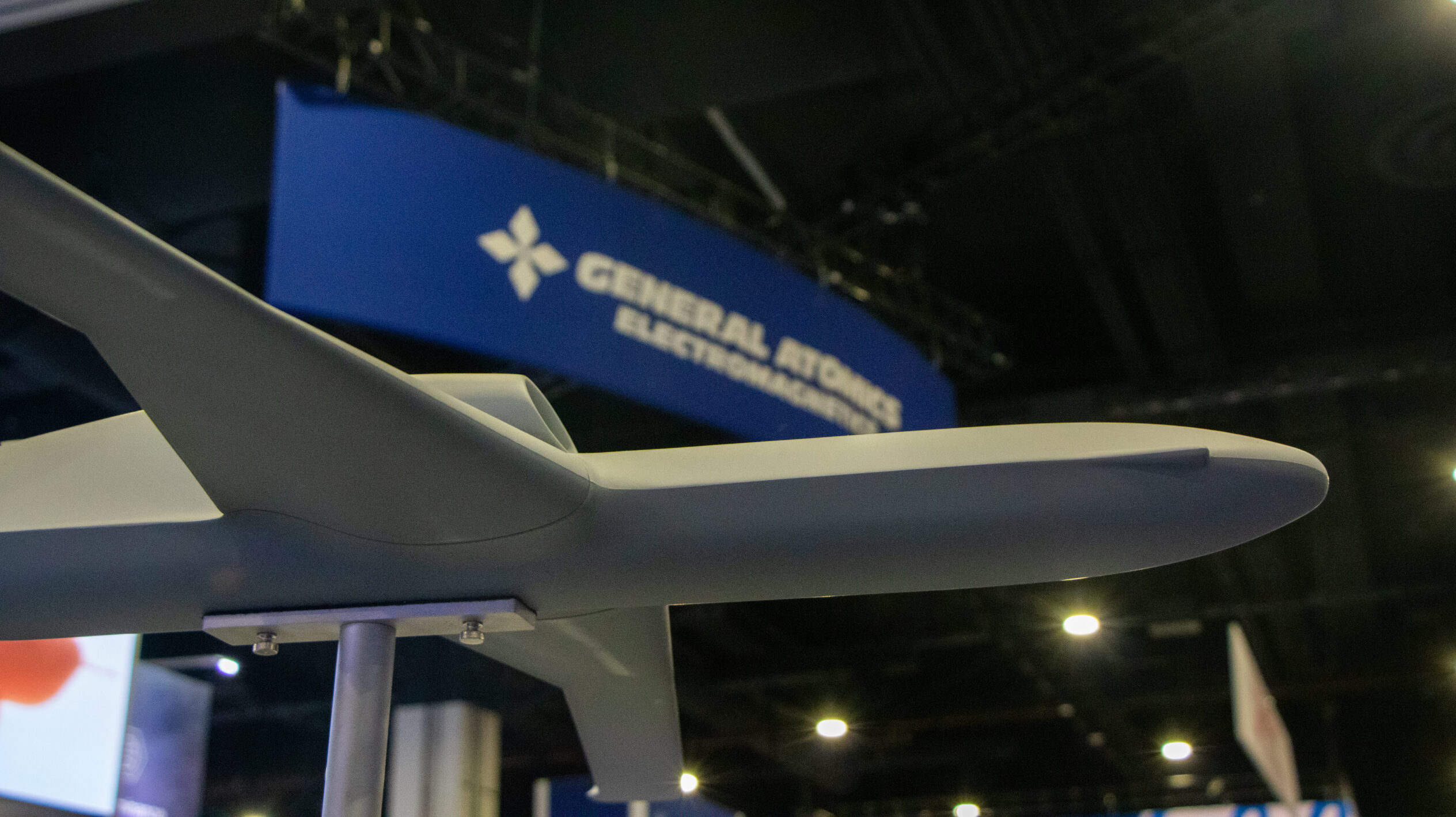

A General Atomics drone model at the AFA 2022 Air, Space and Cyber Conference. (Justin Katz/Breaking Defense)

WASHINGTON — Seeking cheaper, faster production for its unmanned vehicles, General Atomics plans to announce this week a new agreement with commercial automotive 3D printing firm Divergent Technologies, Breaking Defense has learned.

Divergent isn’t known in defense circles, but the company has made inroads in the commercial automotive industry. The startup has signed agreements with a number of car companies, and this year will have parts on the road in Aston Martin vehicles; it has gotten writeups in the New York Times and Forbes. Divergent founder Kevin Czinger has also launched his own line of 3D-printed supercars as a proof-of-concept. The company has raised roughly $700 million through series D funding.

Reached by phone today, Czinger confirmed the agreement with General Atomics. The goal, Czinger said, is for Divergent’s production process to take GA’s existing designs and use additive manufacturing to cut the process down dramatically in both time and cost.

“For example, their structure with fasteners is about 140 pieces for a small unmanned aerial system. We’re taking it down to four, by integrating different structures into the printed structure that we design, manufacture and assemble,” he said. “All of that is done in an automated way. “

For something like a small UAS, “instead of taking years to develop [a design], it takes months, and instead of taking weeks to manufacture by laying out carbon fiber, we take hours to assemble.”

While additive manufacturing is hardly a new technology, Czinger cites nearly 550 patented technologies as part of his technology stack, and claims the company’s production is “15-30 times faster than the fastest state of the art machine” available elsewhere.

Reached for comment, GA spokesman C. Mark Brinkley declined to discuss the Divergent agreement directly. But he did highlight the company’s September announcement of a new Additive Design and Manufacturing Center of Excellence as proof the company is a “disruptor” of traditional practices.

“We believe digital manufacturing and 3-D printing technologies can provide a revolutionary leap forward in next-generation UAS development, and produce fast, impressive results at the lowest cost,” Brinkley said in a statement. “Integrating best-in-class technologies into our process is critical to that effort, and we hope to make some announcements on partnerships in the very near future.”

Teaming with Divergent could have obvious benefits for GA, both as a way to drive down costs on existing systems and as it keeps pace with the global demand for unmanned aerial vehicles — including the upcoming competition for the Air Force’s Collaborative Combat Aircraft program. The CCA effort, currently under development, is envisioned as a set of semi-autonomous, attritable drones designed to accompany next-generation fighter jets. The competition for those next-generation drones could begin in fiscal year 2024, Breaking Defense has reported.

In realistic terms, “attritable” means the system has to be cheap and easy to manufacture, because you expect to lose them during operations. While it’s unclear if CCA was a consideration in the partnership planning, if Czinger’s 3D printing can do what he claims, that would clearly fit the mold.

Another potential benefit, Czinger said, is his confidence that it would be easy to set up a Divergent printing system out in the field.

It would take “weeks” to set up an assembly cell — a hexagonal structure about 22 meters wide — outside the US, which could then begin printing small UAV structures just about anywhere. While the payloads would still need to be assembled and loaded on by traditional methods, a field-production capability has long been the dream of 3D printing advocates. Czinger also pointed out that being downrange with such a setup means that military users could see how a UAV design was performing in the field, take that data in and quickly adjust the design as needed to counter enemy defensive systems.

Notably, Czinger said, he expects the defense and aerospace industry to become a “very significant market” for his company, which is part of the reason he recruited former chairman of the joint chiefs of staff Peter Pace to sit on the company’s board.

GA is “the first [defense] company we started working with, they’re the furthest along and we do have a development partnership with them,” he said, “but they’re not the only aerospace/defense company that we’re working with.”

Lockheed Martin projects potential $1 billion loss on classified program

Lockheed CFO Jay Malave said the company currently expects the program to become profitable on an annual basis around the 2028 timeframe.