HX3 Artillery. Image courtesy of American Rheinmetall.

In this Q&A with Jon Milner, director of business development, Weapon and Ammunition, American Rheinmetall Defense, and Brian Sullivan, vice president of engineering for American Rheinmetall Munitions, we discuss: the performance of its artillery cannons in Ukraine, modernization of the self-propelled M109 howitzer, and their focus on digital engineering capabilities related to work on the XM30 Combat Vehicle.

Breaking Defense: What are the threat scenarios around the world driving the need for artillery cannon modernization, large-caliber industrial base modernization, and propellant modernization?

Milner: The threat scenario is clearly playing out in real time for the world to witness in Ukraine. The specter of large-scale combat operations across the globe is the threat scenario. Right now we see that the Russian style of warfare is to maneuver to position artillery, their “God of War” as they’ve nicknamed it, and then deliver overwhelming mass fires on their adversary. This is what we’ve witnessed in the invasion.

The conflict has become an artillery battle, with NATO and Western allies providing hundreds of howitzers and millions of rounds. Firepower, mass, precision, and range of tactical artillery fires are proving deciding factors on the battlefield. Consequently, Western powers are recognizing the severe lack of investment and innovation in their own artillery capabilities since the end of the Cold War and the Global War on Terror, showcasing a vulnerability in their preparedness for large scale combat operations.

Across the spectrum of your question – cannon modernization, propellant, large caliber industrial base – Rheinmetall has never stopped continuing to invest and innovate in this technology area, and we are therefore well positioned to provide capabilities and solutions for the warfighter in this moment of need with little time to spare.

Breaking Defense: Focusing on artillery cannons, how are Rheinmetall products performing in Ukraine?

Milner: We’re receiving direct user feedback from Ukraine on Rheinmetall’s weapons and ammunition performance from the lowest users up through leadership at the MoD level. To be transparent and frank, the Ukrainians are fighting for their lives and not keeping accurate weapon data record cards that say they fired so many rounds each day and the efficient lifespan of their cannon system is X amount. But our insight is culled from direct user feedback and we know our cannons are being used at exceptional rates – with exceptional results.

During an international conference earlier this year, the Ukrainian chief of artillery (Ukraine’s Colonel Sergei Baronov, Chief of the Main Directorate of Artillery, Missiles and UAVs, General Staff of the Armed Forces of Ukraine) specifically cited verbally and in his slides the PzH 2000 as one of their most reliable and accurate cannon platforms. The German self-propelled howitzer features our world-class 155 millimeter L52 cannon system.

He specifically lauded its high rate of fire. He also praised the DM702 SMArt 155 projectile, which uses two Rheinmetall sensor-fused top attack weapon sub-munitions, in proving it’s worth destroying enemy armored vehicles.

The Netherlands also donated PzH 2000s and they’ve gotten essentially the same positive feedback from the user.

Regarding wear and tear, artillery is particularly hard on barrel life. You have a projectile and propellant wearing the rifling down every time you fire until a barrel essentially becomes unusable or inaccurate.

What we’ve seen with our L52 systems in Ukraine, based on visual inspections and feedback from our maintenance technicians that are doing refurbishments, is that our L52 barrels are maintaining their effectiveness even after upwards of 4,000-plus rounds, which is well beyond what their estimated life is and a reflection of Rheinmetall’s world-class technology and our first-rate manufacturing process.

Breaking Defense: What are US Army needs in this area, and Rheinmetall’s solutions such as the L52 cannon for modernization of the self-propelled M109 howitzer.

Milner: Rheinmetall’s heritage is as an artillery systems house. We do everything from the propellant to the projectile to the fuses to the cannon systems and platforms. We possess an unrivaled understanding of the artillery ecosystem and the effects each of those things has on the other. If you make an adjustment to the cannon or the chamber size, it’s going to have an effect on the projectile and the type or size of propellant.

The Army’s made it clear in their prioritized modernization efforts that long-range fires is number one. They want range and they want overmatch. That’s been loud and clear. The simple reality is the Army’s tactical direct-support field artillery battalions currently using the L39 cannon leaves them outgunned by most allies and even more potential enemies. This isn’t acceptable to any of us.

Rheinmetall’s L52 cannon system offers a ready, essentially off-the-shelf upgrade for the M109A7 Paladin fleet. It’s NATO JBMoU (Joint Ballistics Memorandum of Understanding) standard. It’s in production and in service with nine NATO allies and partners, which means it’s going to be compatible with the current US inventory of ammunition.

For this effort, we’ve teamed with BAE to produce a M109 technology demonstrator, which will debut at AUSA – but more importantly is already taking part in live fire testing. This is about integration versus development, bringing together two combat-proven mature capabilities to provide an immediate path to the range, lethality, and overmatch the Army desires. The Army doesn’t have time for delays or missteps. It needs a modernization path that is low risk, timely in delivery, and exceptional in performance. We’re ready on all fronts.

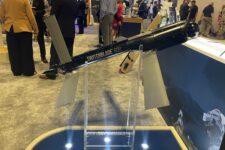

Breaking Defense: The Army is moving forward with a future Next Generation Howitzer, which is supposed to have better mobility and survivability. Tell us about your offering for this program – the L52 and HX3 truck.

Milner: We’re waiting on the results of the Army’s tactical fire study; that’s going to inform the capabilities and solutions of next-gen howitzer needs. We anticipate that it’s likely to be a wheeled platform and a 155 millimeter L52 caliber-length weapon system. Regarding that armament, we’d offer our L52 system for all the reasons we’ve just discussed. It’s proven in service, JBMoU compatible, and we have a history of successfully integrating this exact cannon system onto a variety of platforms, from tracks to wheels and even onto ships.

For the platform, we believe the Rheinmetall HX3 truck, which is competing for the Army’s Common Tactical Truck (CTT) program, is a perfect fit. The HX3 is the next evolution in the successful, capable, and prolific HX truck family – now with critical Modular Open Systems Approach (MOSA), improved survivability, more commerciality, and a suite of advanced driver assistance features. There’s 19 NATO and allied partner user nations of the legacy platform, including close allies like the British and Australians, and you’re able to take advantage of that global logistics backbone, especially when you’re deployed across the globe.

We’ve already produced a prototype, wheeled self-propelled howitzer. We featured it in our AUSA booth in 2019, and that project is on track to live fire in 2024. We are well positioned to address the Army’s needs once they publish them and to do so in a way that offers helpful synergies across programs like CTT and M109A7 modernization, while also simplifying supply chains and providing interoperability with global allies.

Breaking Defense: Describe your digital-engineering capabilities to facilitate progress on these development programs, especially on the Army’s XM30 Combat Vehicle program where American Rheinmetall Vehicles is one of two companies downselected for what was formerly known as the Optionally Manned Fighting Vehicle.

Sullivan: Especially within the US Army, digital engineering is more than a buzzword. It’s a complete approach that the Army is using to develop all future systems.

American Rheinmetall Vehicles is leading our digital engineering efforts to develop a cradle-to-grave process for the XM30 program. They’re using a Modular Open Systems Approach for the vehicle architecture, and part of that entails building a digital twin of the entire system – essentially a complete digital recreation of what the cut metal and run wires would look like for the whole system.

That approach allows the use of advanced manufacturing methods and materials, and reduces development and production times. Testing times are reduced because you can do a lot of the mechanical and electrical testing that you used to have to do with a prototype on the digital twin instead. We’re prepared to bring that integrated digital engineering environment technology into our artillery modernization efforts.

Breaking Defense: Moving to large-caliber industrial base modernization, how is Rheinmetall expanding industrial capability for large-caliber needs to meet modernization demands?

Milner: We’re a global defense firm with vast experience, especially in meeting the growing demand for 155. We have experience setting up new forges and recently set up Rheinmetall NIOA Munitions in Australia to provide a new 155 forge capability for Australia.

Additionally, we have experience in long-range munitions with Rheinmetall Denel Munition in South Africa. We also just acquired Expal Systems, the excellent Spanish ammunition armament manufacturer which expands our reach globally to address demands for 155mm munitions.

We are the European leader in large caliber barrel production, from 120mm to 155mm with a remarkable development and production heritage.

Importantly, we’re always looking to expand these capabilities here in the US. We’re ready to invest, bring competition, deliver capacity, and deliver industrial resilience at a time of clear need.

Breaking Defense: Moving to propellant modernization and capabilities, how is Rheinmetall helping achieve longer range in artillery through better-performing propellant?

Milner: We’ve taken our world-class tank propellant technology and applied it to artillery propellant to produce our Extended Range Charge, or ERC. ERC increases range, particularly when employing a course-correcting fuse for precision targets. Using a course correcting fuse comes with a penalty because of the drag. And what ERC allows you to do is buy back that 10-percent-ish decrement in range that you get from using a course-correcting fuse.

In 2019, we set world distance records for 155mm range at Alkantpan Test Range in South Africa, using ERC to achieve ranges well beyond 60 kilometers and into the 70 kilometer range from L52 systems. We’ve also qualified ERC for L39 and L52 systems, and we’re currently working with the Army DEVCOM Armament Center on an L58 prototype, which is currently in testing and on track for delivery early next year.

We feel that nobody else can match our propellant technology and its temperature-independent qualities across the operational spectrum. Again, we want to deliver these capabilities from US production facilities potentially in direct partnership with the Army such as by utilizing existing Army arsenals.

Breaking Defense: You’ve noted that some key artillery elements suffer from a single source of production in the US like combustible cases. How is the company prepared to invest alongside the US Army to address these chokepoints?

Milner: The conflict in Ukraine and the US government’s supportive weapons, ammo, and resources has revealed some fragility and single points of failure in US production and manufacturing capabilities. One such area is the production of combustible cases.

It’s a true statement that there is just a single source of production in the US for combustible cases for both tank, artillery and mortar munitions. We don’t produce in the US – yet — but we certainly produce combustible cases.

Any kind of modernization is going to put demands on the industrial base. Rheinmetall is prepared to expand industrial capacity, again, where it’s needed, to include things like combustible cases where we have deep experience and technology that we can offer.

We’re prepared to invest alongside the Army to address these choke points as a global leader in production of both combustible cases and 155 millimeter artillery.